|

|---|

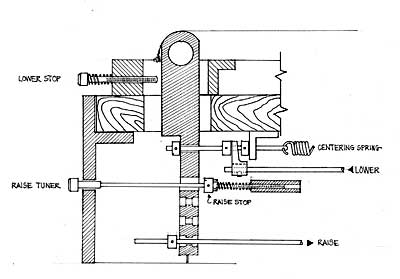

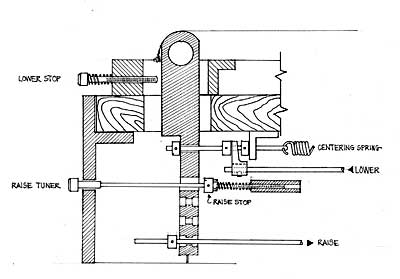

The changer George Sell was using in his guitars was simplicity in itself. The fingers were made from 5/16" 6061 T-6 aircraft aluminum, and ran on a 9/16" steel axle. All he supplied to me were the 12 changer fingers. I made all the accessory parts.

There were several holes going through each changer finger, all with a slight taper on each side to prevent binding of the push or pull rod.

The finger was held at a centered position by a 1/8" rod which had three set-collars attached. The set-collars were lightly soldered in place after assembly through the changer to insure against slippage. The rods went through holes in an "L" bracket fastened to the guitar top. A tension spring (Centering Spring) (connected to another "L" bracket) pulled the rod back. One collar stopped against the bracket. Another collar stopped the finger from moving backwards.

The lower was activated by a rod from the bellcrank onto which was fitted an aluminum yoke which had two arms, one coming down on either side of the lowering rod. The yoke was set-screwed to the lowering rod and rested against the middle collar on the spring tension rod.

When the rod pushed, the arms pushed the spring rod back, releasing tension, and allowing the changer finger to move back. When released, the spring drew the changer back to the center position.

The lower stop was a 10-32 socket head cap screw that was screwed through the changer casting on top. The screw contacted the changer finger directly, stopping its travel.

The raise rods went through one of three holes, and pulled the finger with a set-collar. Somes springs were used between the finger and the set-collar to allow for the fingers to reach their end point of travel at the same time.

The primary (highest note) raises were stopped via a long threaded rod which went though a hole in the changer finger. The rod had a 10-32 socket-head cap screw attached at the end. The rod screwed through a plate that straddled the centering spring unit. A set collar, served as the stop, and a compression spring provided tension to keep the rod from moving on its own. Turning the socket head, turned the rod, and moved the stop back and forth.

If a mid-point raise was desired, it had to be tuned from under the guitar close to the bellcrank.